Welcome to my world of work

This is Luleå Tekniska Universitet. The photo was taken at midday - you can see from my shadow how low in the sky the sun is up here.

A couple of pics of the Uni. I will need to take better ones, but I'm not sure if I'll get any more bright, sunny days.

My office. I was pleased to find that the plants are not real, or they would be dead by now. The desk is also considerably more cluttered now than in this pic.

Question: So what exactly am I doing here?

Graphic answer:

Shortest answer:

Something about making ceramic cutting tools better.

Short answer:

Investigating ceramic coatings on industrial machine tools, to understand how they soften at high temperatures and prevent it from happening.

Longer answer:

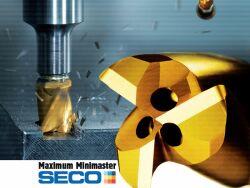

Machine tool inserts (the gold coloured bits in the pic) are the cutting edges of tools used in lathes, mills, drills, reamers, etc. The sintered carbide tools are coated with a TiAlN-based ceramic coating to improve performance. At the high temperatures generated during use the coating decomposes, phase separating into TiN and AlN, and it seems that this occurs initially via a spinodal decomposition process rather than nucleation and growth. We are trying to get detailed evidence and understanding of this decomposition process. This will help design a coating which wont soften as much.

The technique I am focusing on is SAXS - small angle x-ray scattering, which is a technique that hasn't been used to analyse this type of material before. The experiment was performed by my boss Prof. Magnus Oden and his PhD student Peter, while they were in the US using a synchroton x-ray source for this work and for Peter's own research on steels. This was the very first time they have performed such an experiment, and were not sure exactly how it would go. My job is to start by analysing the data they obtained, to determine how well the experiment was performed and how much useful data was obtained. There were experimental problems with a furnace they were using to heat the sample while performing the analysis, (furnace problems - now that's something new!) so there are gaps in the data.

Also, there was simultaneous wide-angle x-ray scattering data (ie. standard XRD), from which I will do stress analysis to see how the extremely high compressive stresses in the film relax during heat treatment. These stresses are what gives the film the intial hardness, and we think that at the early stages of spinodal decomposition the small, self-assembling nano-precipitates produce an age-hardening response in the ceramic (!) that offsets the loss of hardness associated with the stress relaxation.

Now that I've lost the non-materials scientists, let's get back to the question:

So what am I doing here?

a) learning the theory behind SAXS, and learning how to transform the data in the PC and use curve fitting software to analyse the data that was previously obtained

b) learn and do stress analysis of the coatings, and combine all these results with other work that is currently being done and was previously done (DSC, TEM, XRD), to determine what is happening in these materials.

c) Determine what experiments we might need to repeat to get the data we want, and also think about what changes we want to make to the coating to prevent the decomposition from occuring.

This is not so simple. SAXS is an experiment that is easy to perform but difficult to analyse. It relies alot on mathematical operations and curve fitting to try and relate the saxs curve to the real structure in the material. This is not something that comes easy to me - I have mostly been a practical experimentalist - mixing powders to actually make materials, rather than a modeller, so this is a challenge. But that is what I came here for: to learn new things, and expand my knowledge. The connection with my previous work is that the coatings are mostly nitride ceramics, with some carbides, which are materials I have worked with in bulk form before.

I will also be learning how the coatings are made, visiting Seco tools probably in December. We are applying for beamtime in the US to use the synchrotron next year. So yes, it is good that the Aus government is investing money to build one across the road from Monash - there aren't enough of them in the world to cope with demand. Going to Clayton might not sound as exotic as the US or UK or Germany, (well, it might to a Swede!) but I've heard the actual areas the synchrotrons are located in these countries are perhaps even less interesting than Clayton.

Am I enjoying it. Yes. There are some frustrations - every time I get sent a computer script from collaborators in the US it doesn't work on my PC. But the project is interesting, being a fundamental study of a commercially important material, and I think we will get good results. What will it lead to? That I don't yet know...

A couple of pics of the Uni. I will need to take better ones, but I'm not sure if I'll get any more bright, sunny days.

My office. I was pleased to find that the plants are not real, or they would be dead by now. The desk is also considerably more cluttered now than in this pic.

Question: So what exactly am I doing here?

Graphic answer:

Shortest answer:

Something about making ceramic cutting tools better.

Short answer:

Investigating ceramic coatings on industrial machine tools, to understand how they soften at high temperatures and prevent it from happening.

Longer answer:

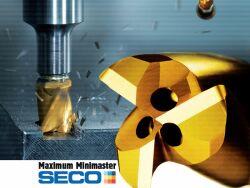

Machine tool inserts (the gold coloured bits in the pic) are the cutting edges of tools used in lathes, mills, drills, reamers, etc. The sintered carbide tools are coated with a TiAlN-based ceramic coating to improve performance. At the high temperatures generated during use the coating decomposes, phase separating into TiN and AlN, and it seems that this occurs initially via a spinodal decomposition process rather than nucleation and growth. We are trying to get detailed evidence and understanding of this decomposition process. This will help design a coating which wont soften as much.

The technique I am focusing on is SAXS - small angle x-ray scattering, which is a technique that hasn't been used to analyse this type of material before. The experiment was performed by my boss Prof. Magnus Oden and his PhD student Peter, while they were in the US using a synchroton x-ray source for this work and for Peter's own research on steels. This was the very first time they have performed such an experiment, and were not sure exactly how it would go. My job is to start by analysing the data they obtained, to determine how well the experiment was performed and how much useful data was obtained. There were experimental problems with a furnace they were using to heat the sample while performing the analysis, (furnace problems - now that's something new!) so there are gaps in the data.

Also, there was simultaneous wide-angle x-ray scattering data (ie. standard XRD), from which I will do stress analysis to see how the extremely high compressive stresses in the film relax during heat treatment. These stresses are what gives the film the intial hardness, and we think that at the early stages of spinodal decomposition the small, self-assembling nano-precipitates produce an age-hardening response in the ceramic (!) that offsets the loss of hardness associated with the stress relaxation.

Now that I've lost the non-materials scientists, let's get back to the question:

So what am I doing here?

a) learning the theory behind SAXS, and learning how to transform the data in the PC and use curve fitting software to analyse the data that was previously obtained

b) learn and do stress analysis of the coatings, and combine all these results with other work that is currently being done and was previously done (DSC, TEM, XRD), to determine what is happening in these materials.

c) Determine what experiments we might need to repeat to get the data we want, and also think about what changes we want to make to the coating to prevent the decomposition from occuring.

This is not so simple. SAXS is an experiment that is easy to perform but difficult to analyse. It relies alot on mathematical operations and curve fitting to try and relate the saxs curve to the real structure in the material. This is not something that comes easy to me - I have mostly been a practical experimentalist - mixing powders to actually make materials, rather than a modeller, so this is a challenge. But that is what I came here for: to learn new things, and expand my knowledge. The connection with my previous work is that the coatings are mostly nitride ceramics, with some carbides, which are materials I have worked with in bulk form before.

I will also be learning how the coatings are made, visiting Seco tools probably in December. We are applying for beamtime in the US to use the synchrotron next year. So yes, it is good that the Aus government is investing money to build one across the road from Monash - there aren't enough of them in the world to cope with demand. Going to Clayton might not sound as exotic as the US or UK or Germany, (well, it might to a Swede!) but I've heard the actual areas the synchrotrons are located in these countries are perhaps even less interesting than Clayton.

Am I enjoying it. Yes. There are some frustrations - every time I get sent a computer script from collaborators in the US it doesn't work on my PC. But the project is interesting, being a fundamental study of a commercially important material, and I think we will get good results. What will it lead to? That I don't yet know...

0 Comments:

Post a Comment

<< Home